The Potential of 3D Screen Printing to Combat Counterfeit Medication

- Laxxon Medical

- Apr 8, 2024

- 3 min read

Could 3D screen printing offer unprecedented anti-counterfeiting strategies for oral solid dosage forms that would be feasible for large-scale production?

The World Health Organization (WHO) estimates that almost 10% of global pharmaceutical commerce, or $21 billion worth, involves counterfeit drugs. While the problem is more prevalent in 3rd world countries, it’s not an isolated issue, and it’s not going away.

In 2021, Interpol’s worldwide operation discovered more than 3 million counterfeit medicines and medical devices in the UK supply chain worth GBP 9 million. Another operation by Europol seized more than 25 million units of medicine with a value of around EUR 63 million.

In a recent study published in the MDPI, Laxxon Medical examines the benefits 3D screen printing could potentially offer to reduce the impact of counterfeit medication while improving safety for patients worldwide.

Identifying Counterfeit Medication

It’s no easy task to identify counterfeit medication. Physical features such as labeling, packaging, appearance, spelling mistakes, and product security features can all be used to identify a counterfeit drug, but only a poorly made one.

Currently, the FDA supports several anti-counterfeit detection methods and techniques, including tamper-resistant packaging, trace and track technology, product authentication, and forensic security features such as chemical or biological tracing, which are introduced into a tablet. However, forensic testing is expensive and unlikely to be made available to the general public.

This makes the implementation of anti-counterfeiting measures directly onto the tablet a necessity. If possible, a combination of hidden anti-counterfeiting measures and easily recognizable visual features would be the goal, helping authorities track counterfeit medication while allowing the general public and dispensers to visually identify suspicious medications.

3D Screen Printing and the Solution It Offers to the Global Counterfeiting Crisis

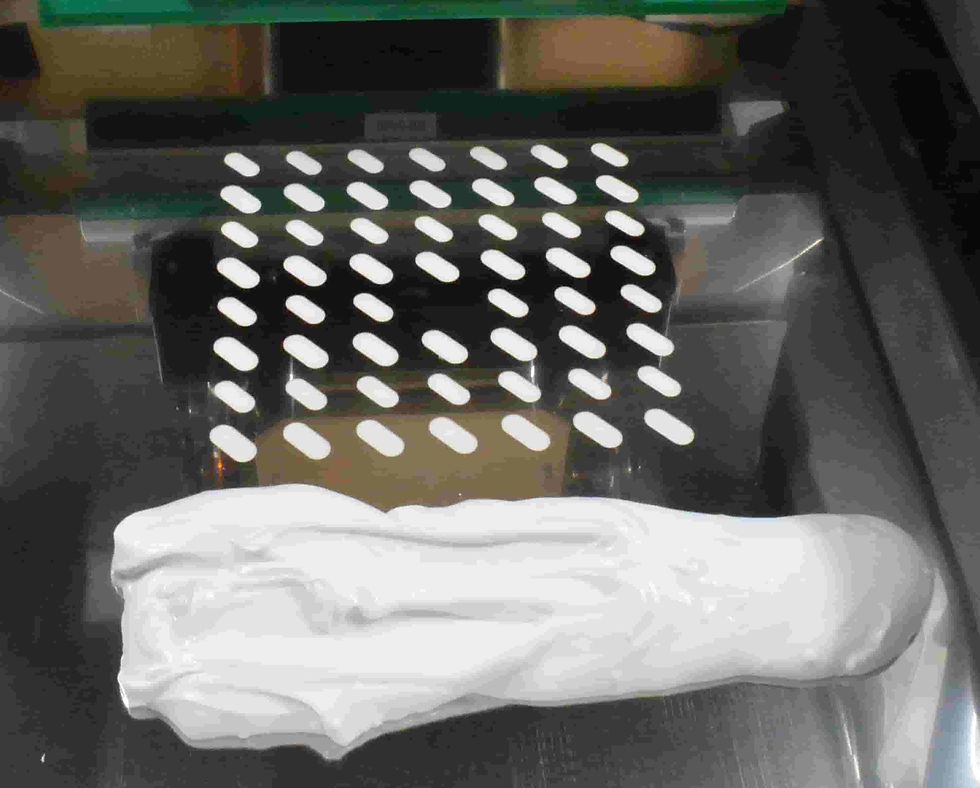

By utilizing the advantages of 3D screen printing (Laxxon Medical GmbH, Jena, Germany, US Patent 20140065194), an aqueous dispersion of excipients and API are printed through a screen mesh onto a substrate, thousands of strongly defined tablets can be printed per screen simultaneously.

The shape is defined by the layout of an impermeable emulsion that blocks certain areas on the mesh. After one printing cycle, the deposited layer is dried. The next layer is printed precisely on top of the previous one after lifting the screen by the thickness of the dried layer. Subsequently, a three-dimensional geometry is constructed.

Laxxon Medical Corp. (New York, NY, USA) has already developed a proof-of-concept work with 3DSP (SPID®-Technology, Stetten, Switzerland), having shown its anti-counterfeiting potential by printing QR codes directly on tablets as small as r = 5 mm during and as an integral part of the manufacturing process.

Since 3D screen printing with SPID® technology is a tightly controlled and licensed manufacturing technology that isn’t generally available, it’s impossible to mimic these features in an uncontrolled environment and without extensive technological and development resources, which means that the technology doesn’t lend itself to easy duplication.

Along with overt anti-counterfeiting measures such as imprinted QR codes, 3D screen printing technology also has the ability to offer covert features included within oral dosage forms, which are impossible to counterfeit using the available conventional methods.

By embedding a covert cross structure into a tablet and only two screen-and-paste changes, a structure can be integrated into a tablet that exhibits a distinct pattern upon the breakage of the tablet in either the middle or slightly off-center. Additionally, the only difference in the paste compared to the overall tablet material is the addition of food coloring, meaning only a subtle change in API content due to the addition of food coloring and no strongly irregular API distribution in the tablet. This means that no alteration in the biopharmaceutical performance would be expected compared to a homogenous tablet without the embedded cross.

3D Screen Printing to Combat Counterfeit Medication

The study showed that through 3D screen printing technology, the manufacture of tablets with a distinct inner architecture could be integrated at a large scale.

This innovative approach demonstrates the power of 3D screen printing to implement novel and innovative anti-counterfeiting measures in manufacturing solid oral dosage forms. The method’s simplicity and adaptability to other formulations make it a potential solution to enhance drug security, pushing the frontiers in the fight against counterfeit drugs in favor of patients and even the stakeholders involved in the pharmaceutical industry.

You can read the complete study here.

Laxxon Medical is dedicated to engineering patented 3D pharmaceutical solutions that optimize products and benefit patients. Our goal is to establish SPID®-Technology as a manufacturing process with the individual and the pharmaceutical partner in mind.

To keep up to date with SPID®-Technology and Laxxon Medical news and announcements, follow us on LinkedIn.